Filling Volume (Per Month):10k

Cost Analysis

Hand Filling:

- Labor Time – 83.33 Hours

- Labor Cost – $1,249.95/Month

Machine Filling:

- Labor Time – 83.33 Hours

- Labor Cost – $124.95/Month

Savings Analysis

- Labor Savings – $1,125 / Month

- Pay-back Time – 11.11 Months

ROI

Year 1 ROI+ $1,012.50

Year 2 ROI+ $13,500

Filling Volume (Per Month):20k

Cost Analysis

Hand Filling:

- Labor Time – 166.67 Hours

- Labor Cost – $2,500.05/Month

Machine Filling:

- Labor Time – 166.67 Hours

- Labor Cost – $249.90/Month

Savings Analysis

- Labor Savings – $2,250.15 / Month

- Pay-back Time – 5.56 Months

ROI

Year 1 ROI+ $14,490.97

Year 2 ROI+ $27,001.80

Filling Volume (Per Month):50k

Cost Analysis

Hand Filling:

- Labor Time – 416.67 Hours

- Labor Cost – $6,250.05/Month

Machine Filling:

- Labor Time – 416.67 Hours

- Labor Cost – $624.90/Month

Savings Analysis

- Labor Savings – $5,625.15 / Month

- Pay-back Time – 2.22 Months

ROI

Year 1 ROI+ $55,013.97

Year 2 ROI+ $67,501.80

Our filling systems are proven to be within +/- 1% pump accuracy, while other systems and methods start at 2% or more. That is a minumum of 1% material savings on every cartridge. 1% multiplied by your daily fill quotas can add up to thousands of dollars in a very short period of time!

More Product Info

CFS-1000 Filling System

The CFS-1000 Cartridge Filling Machine fills 1,000 cartridges per hour, just place the cartridge in position and the machine will automatically raise, fill and bring then cartridge back down.

Product Highlights

- Fill Rate: Up to 1,200 1/2 gram cartridges per hour

- Delivery Volume Range: Unlimited. Settable by Pump Head Angle Adjustment

- Vessel Volume: 843 grams

CFS-1000M Filling System

Credence Filling Systems' newest manual machine capable of 1,000 cartridges per hour, just place and slide the cartridge up to the needle to fill.

Product Highlights

- Fill Rate: Up to 1,200 1/2 gram cartridges per hour

- Delivery Volume Range: Unlimited. Settable by Pump Head Angle Adjustment

- Vessel Volume: 843 grams

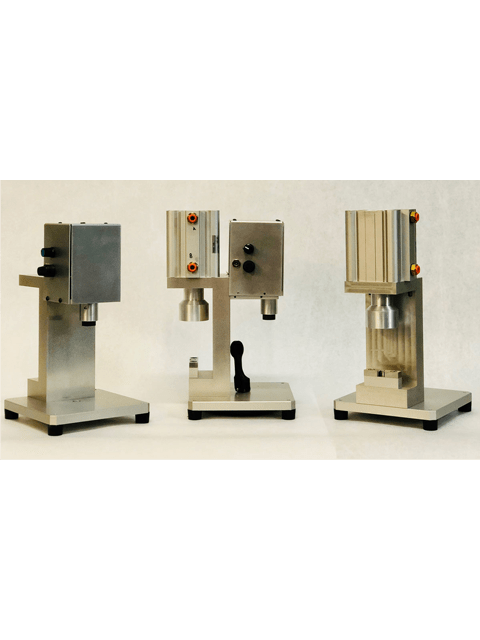

CCS-1000 Capping System

The Credence Capping System presses on mouthpieces in addition to threading on caps. Simply spin the machine around. Available as a singular function machine for pressing mouthpieces or threading caps as well as in dual function machines which do both.

Product Highlights

- Dual - $5,000

- Will cap any screw-on cap or press-on cap

- Available as just a Rotary, just a Press-On, or a Dual System

Cartridge Filling Systems

Credence Filling Systems offers the very best in cartridge filling systems. We provide affordable tools to extractors and dispensaries looking to bring a brand in-house and establish relationships with cartridge distributors. Our machines are user-friendly, accurate, allow for repeatable filling, and achieve consistent fill weights.

Cartridge Cappers

Credence Filling Syatems offers the ultimate in efficiency. Our Cartridge Cappers eliminate wasted time. We replaced the tedious manual task of screwing on caps with an automated process. Investing in a Cartridge Capping machine is cost-effective. You reduce overhead costs, increase efficiency, and maximize the profitability of your bottom line.

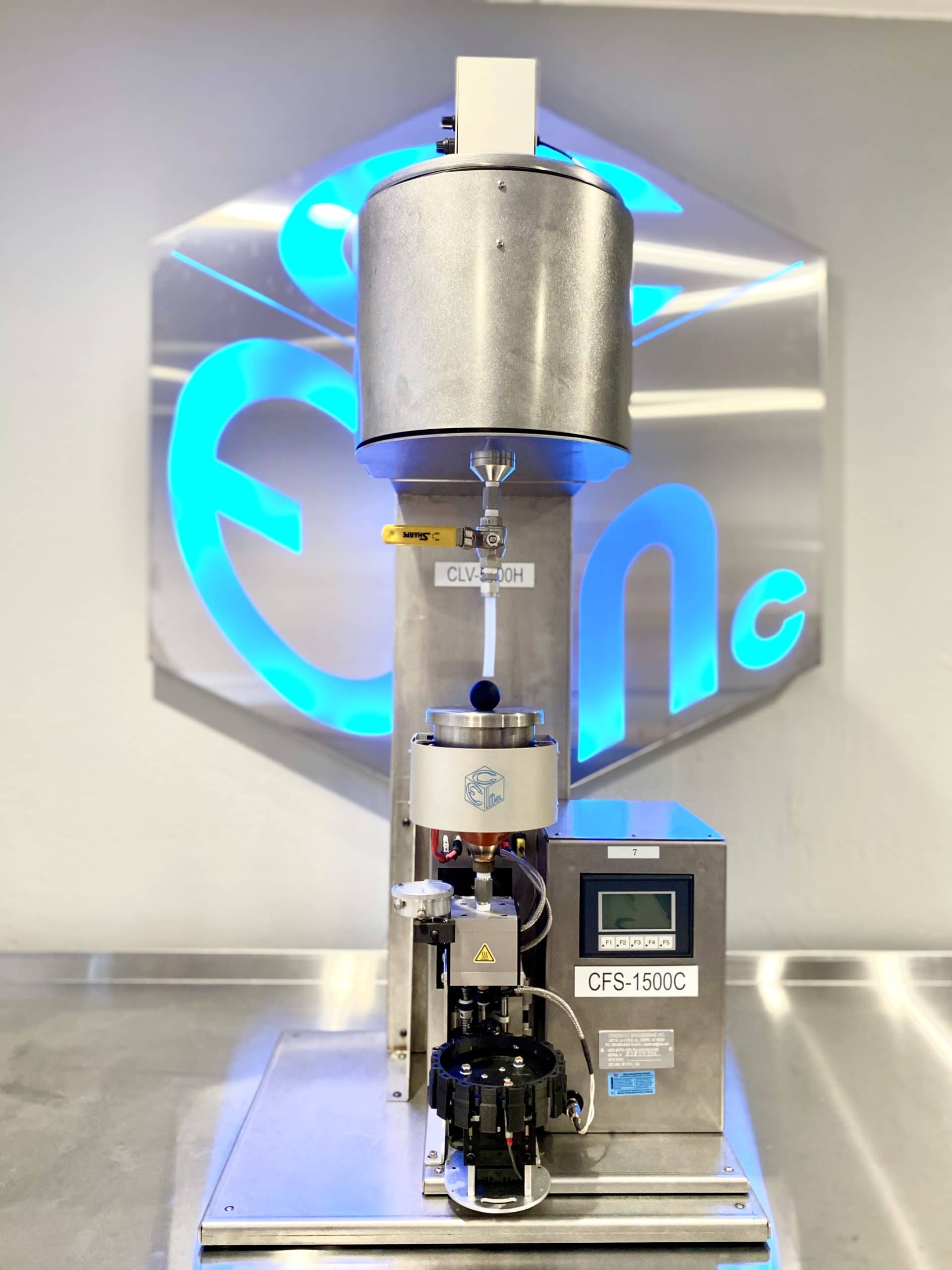

CLV-5400 Vessel System

The CLV-5400H Large Vessel System is designed to work in conjunction with one of our Cartridge Filling Machines. The large base provides a stable base on which the filling machine resides placing the filling machine vessel directly below the large vessel. The CLV-5400H is constructed from heavy-duty 304 stainless steel. It has a stainless ball valve to deliver material to the filling machine vessel.

The CLV-5400H provides up to 5400 ml of vessel capacity for those customers that fill larger volume devices such as tincture bottles or vials. The CLV-5400 is available with heat and temperature control for those customers whose product is THC based and needs elevated temperatures for the material to flow properly. The CLV-5400H comes with heaters attached to the large vessel, a thermocouple temperature probe, a programmable temperature controller, a laser level sensor to let you know when the vessel is approaching empty, and a vessel stirring apparatus to keep all of the terpenes etc.in suspension.

Product Highlights

- Oils it can deliver: All Types, Distillate, CO2, CBD, CO2 Infused, etc.

- Throughput Potential: Up to 300 30 ml devices per hour

- Vessel Volume: 5450 mL

- Power Requirements: 110V AC 10A

- Change-Over time between lots: As little as 5 Minutes

- Cleanout: Ethanol

- Temperature Range of Vessel: Ambient to 80C (Adjustable in 1 degree Increments).

- Shipping Weight: 60 lbs.

CCS-1500C Capping System

The CCS-1500CP is a Press-Type Capping System coupled with our Carousel Feeding Mechanism to give you the highest throughput in a reasonably priced capping solution.

By eliminating the load and unload from the capping cycle, we have created a capping solution that is both easy to use and highly productive. The CCS-1500CP can process carts as fast as you can place the mouthpiece onto the cart and drop it into the carousel. This unique design is capable of a 1-second cycle if it were possible to place the cap and drop the cart into the carousel at that rate. At any rate, the CCS-1500CP will cap through your daily needs faster than any system on the market.

Product Highlights

- Will cap any press-on cap

- Interchangeable tooling for the desired cap.

- Automatic Operation

- Throughput Potential: Up to 2400 devices per hour.

- Air Pressure Regulated: 100 psi 5 CFM required.

- Manual Insert into Nest.

- Automatic Eject

- 110VAC 5A

- Manually load cap and place into rotary Carousel.

- Throughput potential up to 2400 per hour.

- Shipping Weight: 40 lbs.

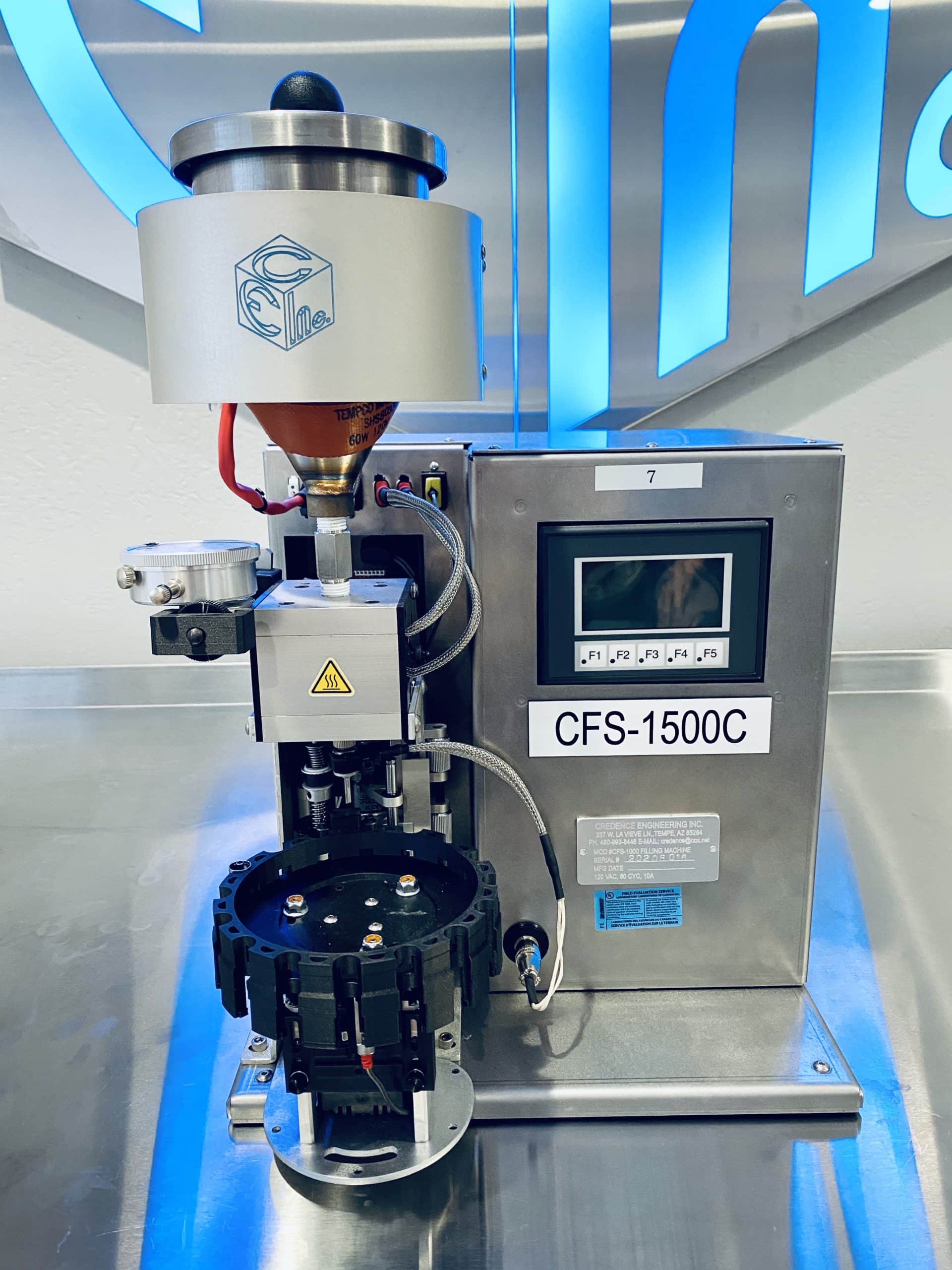

CFS-1500C Filling System

The CFS-1500C Carousel Filling System is an extension of our CFS1000 Filling Platform. With the addition of our new carousel feeder and our new software, the CFS-1500C takes an already productive workhorse into the manufacturing age. By eliminating the load and unload of the fill cycle, the carousel feeder creates an easy-to-use filling system that is non-tiring and very productive.

The Carousel is driven by a smart stepper motor and utilizes a reflective sensor to know that a cart has been loaded. By using dual sensors, the carousel feeder is smart enough to know if there is a cart present at the fill station. In the event that the operator misses a position in the carousel, the sensor at the fill position will know that a cart is missing and will automatically skip that position and go on to the next. The carousel feeder takes a potential 1000 per hour process and converts it to a true 1500 per hour process.

Positional braking is incorporated into the elevator mechanism on the carousel mechanism to minimize the over-travel and keep the entire process crisp and productive.

Product Highlights

- Oils it can deliver: All Types, Distillate, CO2, CBD, CO2 Infused, etc.

- Devices it can Fill: All “Top Fill” Types of Cartridges, Pens, Disposables, Pods, Syringes, etc.

- Delivery Volume Range: Unlimited. Settable by Pump Head Angle Adjustment and number of pump revolutions.

- Throughput Potential: Up to 1500 half-gram devices per hour

- Vessel Volume 843 grams (Larger Vessel Available)

- Filling Accuracy: +/- .005 grams.

- Power Requirements: 110V AC 10A

- Change-Over time between Lots: As little as 2 Minutes.

- Change-Over time between Devices: As little as 15 Minutes.

- Cleanout: Ethanol

- Temperature Range of Vessel: Ambient to 100C (Adjustable in 1 degree Increments).

- Pump Temperature Range: Ambient to 100C (Adjustable in 1 degree Increments).

- Needle Heater Temperature 65-80C (Unadjustable

- Shipping Weight 30 lbs.

CMS-3000 Array Attachment

The CMS-3000 is an attachment that fits all Credence Filling Machines except the ACFS-4000T Automatic. It speeds the process for filling cartridges packaged in array form (in a foam block etc.). This ensures the same accuracy and repeatability to which you are accustomed when using Credence equipment, while also enabling you to keep the cartridges packed in the array block as you use the needle remotely fill the cartridges. It takes out the step for you to unpack and repack the cartridges from the array block, thereby saving you significant labor cost.

Product Highlights

- Oils it can deliver: Only recommended for distillate.

- Devices it can Fill: All “Top Fill” Types of Cartridges, Pens, Disposables, Pods, Syringes, etc.

- Delivery Volume Range: Unlimited. Settable by Pump Head Angle Adjustment.

- Throughput Potential: Up to 3000 half-gram devices per hour.

- Filling Accuracy: +/- 1%.

- Power Requirements: Connects to Credence Filling Machine.

- Change-Over time between Lots: As little as 2 Minutes.

- Change-Over time between Devices: As little as 5 Minutes.

- Cleanout: Ethanol

- Needle Heater Temperature 60-80C (Switchable)

- Shipping Weight 2 lbs.

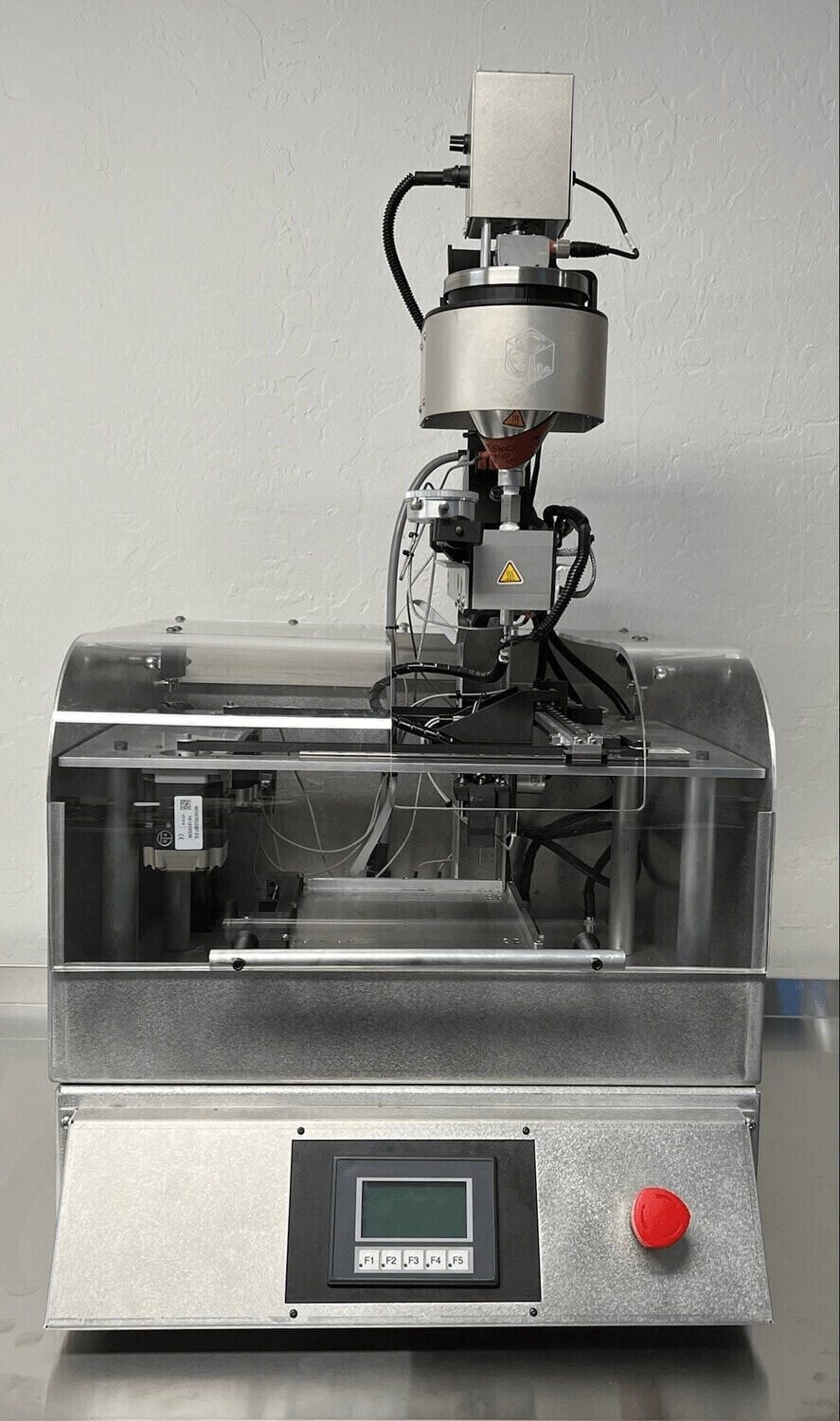

ACFS-4000T Auto Filling Machine

The ACFS-4000T is the most productive Cartridge Filling Machine on the market today. It will fill up to 3600 1.0 gr and up to 4200 .5 gr cartridges per hour. It is based around the CCell and Bold injection-molded tray concept where the cartridges are accurately positioned so the XY motion system can quickly place a needle in each cartridge and fill the cartridge using the Credence Pump, which is the most precise and fastest delivery system available.

The ACFS-4000T has full temperature control through the oil path. The Vessel, the Pump, The Flexible Line to the Needle and the Needle are all independently temperature controlled for the toughest oils.

The XY Motion is a proven design and will give long service with minimal maintenance and downtime. Instead of moving the bulky tray of carts to each position like most array fillers, The ACFS-4000T moves the needle assembly, which is a much lighter load. This keeps the motion load consistent, whereas other array fillers move the Cartridge array, which continually increases in mass as the carts are filled. Another innovation of the ACFS-4000T that affects its speed is the Needle Z motion where the needle will move down and up in 1/3 of a second total. The needle motion is ½ of the total cycle time so it must be fast if the machine cycle time will achieve a 1 second cycle time. It is designed around a fast-acting DC Gearmotor Cam Drive to insure consistent needle entry into the cartridge while clearing the cartridge quickly so the XY motion system can move the needle to the next position.

The tray of cartridges loads onto a stepper motor driven Elevator that will set the top of the cartridges at the optimum height for filling. A simple menu selection will change the cart volume from .5 gr to 1.0 gr which correlates to the height of the elevator for filling.

Another key innovation is the Patent-Pending Credence Cart-Top Alignment tray. It holds the tops of all of the cartridges in the exact location and shields the outer rim of the cart so the needle is guided into the cart automatically.

We have incorporated some software-hardware innovations to prevent inadvertent loss of oil should a couple of conditions happen: 1) if the cartridge center tube is eccentric to the outer rim and the needle hits the center tube instead of going into the cart, the software senses the mishap and stops the pump from dispensing for that cart. The system just skips that cart and goes onto the next one without losing any production time. The position of the cart within the array is displayed on the User Interface Screen so the operator can remove that cart prior to capping. 2) We incorporated timing belt failure mechanism/sensors in the unlikely event that a belt breaks or comes loose allowing the needle position to be compromised. Should this happen, the idler tension pulley swings under a sensor that alerts the controller that a belt has failed. The controller, in turn, automatically stops the cycle before any oil is lost. An alert will be displayed on the screen telling the operator that maintenance is required.

The ACFS-4000T is the most sophisticated Cartridge Filling System on the Market and will give your many years of productive Cartridge Filling. Credence also continually improves its products and will offer and new innovations to ACFS-4000T owners as they are proven.

Product Highlights

- Array Filling up to 100 carts in less than 2 minutes

- Uses BOLD and CCell injection molded tray

- Simple Setup

- Door interlock

- PLC Controller

- Fills 100 array non-stop

- Requires heavy duty base/table

- Filling Accuracy: +/- 1%.

- 110 VAC 10 Amps

- Shipping Weight 55 lbs.

CCS-1000P Capping System

The CCS-1000P is a single load pneumatic press capping system for cartridges that require press on caps. Included with the machine are three sets of pneumatic tubing, an air regulator, a 24V DC wall transformer, and nests for standard caps. The air regulator features a foot pedal that is pushed to force air to the machine to secure a tight seal on the cap. The throughput potential is up to 1200 devices per hour. In addition, we offer an extremely quiet and efficient air compressor that is modified for the pneumatic tubing for purchase with this machine.

CCS-1000R Rotary Capping System

The CCS-1000R is a rotary capping system for cartridges that require twist on caps. The machine features interchangeable tooling for various caps such as duck bill and flat bill caps. Included with the machine is a 24V DC wall transformer. The machine features a hollow compliant rotary tool that is tapered internally and variable speed control. The throughput potential is 1200 devices per hour.

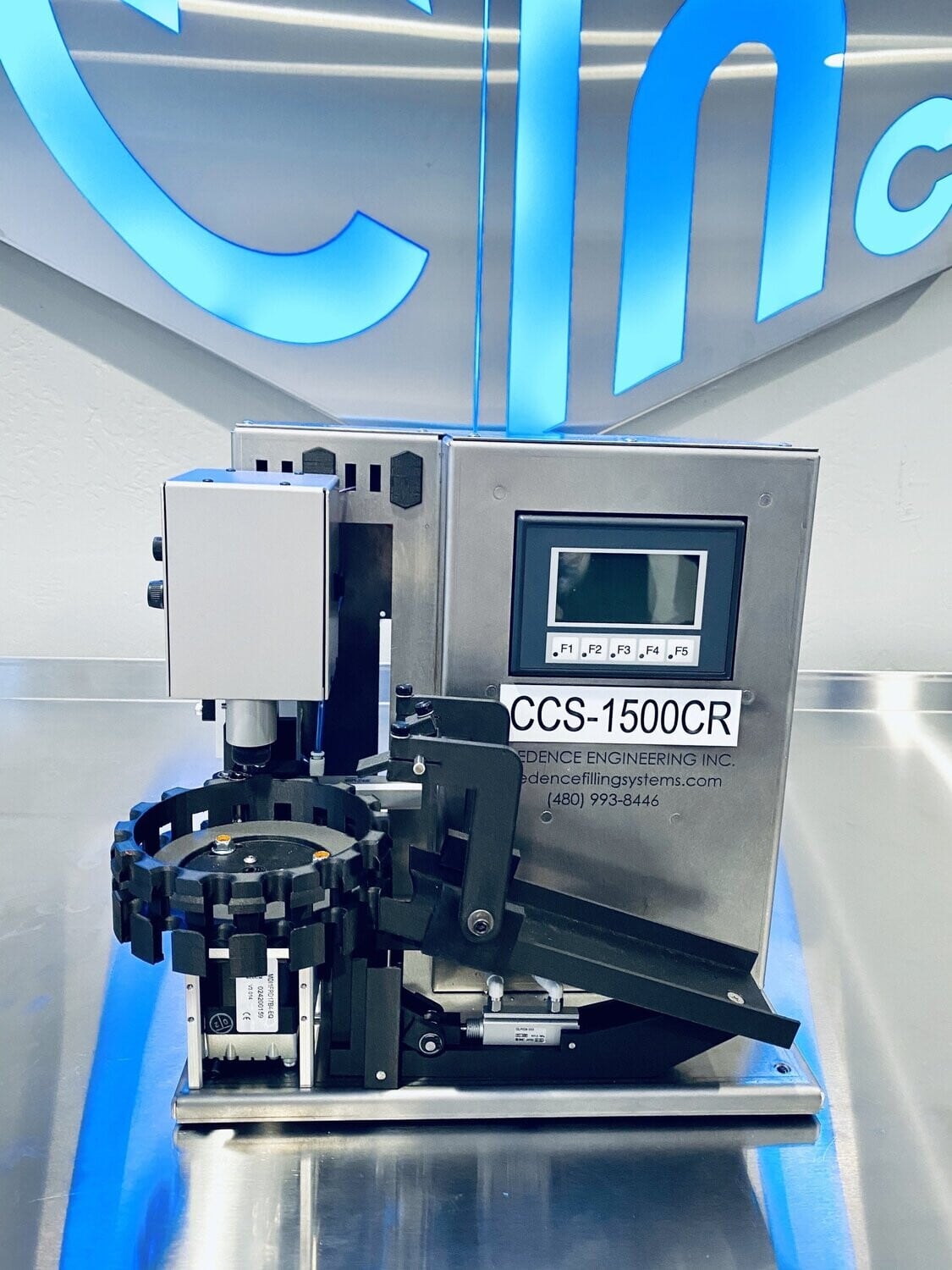

CCS-1500CR Carousel Rotary Capping System

The CCS-1500CR Carousel Feed Rotary Capping System is a State-of-the-Art, Highly Productive Capping System for rotary-style mouthpieces. By incorporating our Carousel Feeding System with our proven rotary Capping Process, we have developed a rotary capping process that is not only highly productive, but also easy to use and non-fatiguing. By incorporating our reliable Cart ejection system, the operator only needs to be concerned with placing the mouthpiece and the cart into the Carousel. The removal of the finished capped cart is automatic which allows the operator to focus on the heart of the process...Capping Carts.

Similar to our CCS-1500CP the CCS-1500CR Carousel Feed Rotary Capping System is only secondary to one of our Fully Automatic Fill and Cap solutions.

Product Highlights

- Will cap any screw on cap

- No setup required between models

- Throughput potential: Up to 2,000 devices per hour.

- Air pressure regulated.

- Manual insert into nest

- Automatic eject

- Power requirements: 110VAC 5A

- Shipping weight 30lbs

CCS-18000T Capping System

The CCS-18000T is the most productive Cartridge Capping System on the market. It will keep pace with up to five (5) Credence CFS-4000T Automatic Cartridge Filling Machines, whose combined output can reach up to 18000 filled and capped vape cartridges per hour using only a single operator to do so.

The CCS-18000T not only caps all 100 cartridges simultaneously, but it has two special features that set it apart from all competitors. The first is the fact that this system is not predicated on setting the correct pressure based upon how many carts you are capping or what type of carts you are capping. The ram press height is based upon a distance measurement from the bottom of the cart to the top of the mouthpiece. The distance to which the ram comes down is a set value in the software. Once you determine and set the ram press height, you can cap 1, 2, 50, 100 or anything in between without worrying if the smaller quantities are in danger of getting smashed. The competitor’s machines must have the air pressure adjusted to match the quantity of carts being capped and failure to match the pressure with the cart quantity can end up in lost product.

The second unique feature of the CCS-18000T is that the Upper Tooling set is actually 100 individual presses that compensate for the differences in cart overall height due to cart component size variation. Normal carts can vary up to 1 mm in overall height from one lot to another and this difference in height must be taken into consideration when setting up the array capper. Not so with the CCS-18000T. Once you set a height for a given product, that height value should never change. It should be checked during each new lot setup, but you will find that the CCS- 18000T is very consistent across all of your products.

PRI-600 Pre-Roll Infusion Machine – Coming Soon!

Using this machine, concentrate is distributed evenly down the center of the pre-roll. For operators to ensure the product meets spec, the machine will include a digital scale and infrared camera. 600+ pre-rolls can be infused per hour. The machine, with additional nests and components also has the capability of filling cartridges and disposables.