FAQs

What are the benefits of using a filling machine versus filling by hand?

Filling by hand presents human error, potentially contaminates and can be tedious and

time-consuming.

Filling by hand becomes fatiguing for employees. By using a filling machine, you will increase your throughput with less labor required and the filling consistency and accuracy are superior.

Can your machines be scaled so we can increase our throughput as we grow?

Most of our filling machines can be scaled with the exception of the ACFS-4000T. Below are some examples. We can also customize machines to cater to your specific needs.

*The CFS-1500C can start as a CFS-1000, then upgraded to a CFS-1500C

*For the pre-roll infusion machine, a carousel system can be added to increase throughput

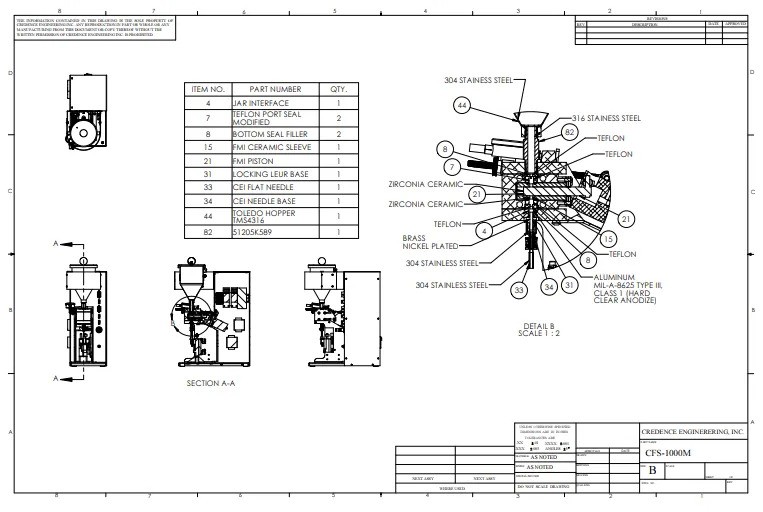

*On the CFS-1000M, add a CMS-3000 Mobile Shot to increase throughput.

*The CFS-1000M and CCS-1000 can be wired together in tandem for one operator to be able to fill and cap simultaneously.

*A foot pedal can be added to the CFS-1000M,

in lieu of the module

How can we prevent overfilling or underfilling our devices?

Our machines fill within +/- 1%

of the set weight.

The correct temperature

must be set to accommodate

your type of oil.

Using automated filling equipment

can greatly improve the accuracy of your oil filling operation.

The repeatability rate ensures the most accurate dispensing possible…the lower the % the better!

Where are your machines made and am I able to get replacement parts if needed quickly?

Our machines are manufactured in

Tempe, AZ

U.S.A.

Replacement parts are in stock and can be shipped within

27 hours.

Are we able to lease the equipment?

We can refer you to our partner leasing companies if you would like to lease our machines.

Why would I buy new versus a used machine on the market?

Buying new will guarantee your machine is top quality and servicing, when needed, is readily available.

When you purchase a used machine, make sure you will have access to timely service and replacement parts when you have a need.

Also, it is highly recommended you get maintenance records and SOPs for any used machines you purchase.

How do we ensure the oil that goes into our devices maintains its quality?

If your oil is formulated correctly, it won’t have any issues with our machines.

Our machines are designed to protect the integrity of your oil.

The vessel stirrer that comes with all filling machines keeps the oil moving around in the vessel, keeping the temperature even throughout.

Inside the pump on every machine, we have a cylinder pump (ceramic piston and sleeve) completely enclosed at all times until you press the run button.

You can add nitrogen into the vessel, and have a weighted lid, and can put in an

air -take as well.

(Fluid Path below)

What happens if our Credence machine needs service?

We will schedule a call to troubleshoot via phone first.

If it cannot be fixed via phone call, we will request you send the machine to us to be fixed (shipping is the responsibility of the customer).

If you would like us to send you a

*loaner* machine while your machine is being fixed,

we are happy to do so

(shipping is again, the responsibility of the customer).

What mouthpieces work with your machines?

Our tooling is universal and fits all standard mouthpieces with or without silicone.

If we cannot accommodate

the size of your mouthpiece,

we will design

and

build it for free.

What capabilities can the automatic ACFS-18000T and CCS-18000T capper do in terms of maximum production?

With five [5] ACFS-4000T machines and 1 CCS-18880T machine, the combined output can reach up to *18,000 filled and capped cartridges*

per hour

with just one operator.

How will I know if your machines will work with my oil’s viscosity and temperature requirements?

Give us a call so we can discuss it.

We will need to know what temperature you are trying to run your oil at and what viscosity your oil is.

The thicker the oil,

the better it works with our machines

Will the automatic filling machine ACFS-4000T fill disposables?

We can customize the filling machine to accommodate disposables.

Provide us samples of your disposables and we can evaluate them.

Upon your approval,

we would have a

3-5 week lead time

to complete the build.

Can the ACFS-4000T fill cartridges while in the foam tray?

No, our ACFS-4000T automatic machine works with the Bold or CCell injection molded trays.

Trays can be purchased through Credence.

Can you adjust the CCS-1000 capping machines to fit disposables?

Yes

we offer a riser for US$150.00

that adds 2” of height

to accommodate

most disposables.

Are Credence Filling Systems UL certified?

Our machines can be and have been

UL certified at the customer request.

Customer is responsible for the associated cost.

Does Credence meet GMP Certification?

Credence Engineering follows GMP practices but is not currently certified.

We are currently in process of getting

GMP certification.

Is the torque adjustable on your capping machines?

On our CCS-1000R capping machine,

the torque is not adjustable,

however there is a clutch on the capper and the speed is set to give you the correct amount of torque.

On the CCS-1500R capping machine, the torque is adjustable.

Do your machines all fit on a table top?

Yes,

our machines are compact and require a small footprint,

allowing more space for your production team’s projects.

Can the vessels be switched from small vessel to large vessel on the machines?

The large vessel system is a separate purchase and can accept any filling machine except the automatic.

We are currently developing a removable vessel system for customers who produce small lots and use a variety of oils.

Can we use cartridges with and without screw protectors in your machines?

Yes, all machines can accommodate either.

What types of oil do your machines work with?

*All types*

Distillate, CO2, CBD, CO2 Infused, etc

What types of devices do your machines work with?

Top Fill Cartridges, pens, disposables, pods, syringes, and tincture bottles

(except with CFS- 600T2).

Bottom Fill-septum piercing cartridges can be filled with our CFS-600T2 machine.

Will the single load capping machine work for both cartridges and disposables?

It can be built to your specific needs.

It is equipped with multi-purpose tooling that will work with almost every cap with or without silicone.

Does the CFS-1000M fill both 0.5g and 1.0g devices?

Yes!

The machine is based on a single pump cycle

and fixed pump speed.

o fill a 1.0g device,

you cycle it twice,

which is quite rapid.

Why choose Credence Engineering?

As a family-owned and operated company,

we continue to put our more than two [2] decades of experience to extremely good use.

Takomg every opportunity to improve, advance

and continue to pave the way for accurate and efficient

*True Short Path Systems*

for the Vaping Community.

We continually upgrade our products and offer the upgrades free of charge (the customer is responsible for shipping costs).

What payment methods do you accept?

We accept wire transfers, Zelle – cash and credit cards with a 4.5% fee.

ACH transfers are not accepted.

What shipping methods do you use?

FedEx is our preferred

method of shipping.

All shipping rates are calculated by FedEx and determined by the size, shape, and weight of the product.

Alternately, you may use your own shipping company and we will coordinate with them

for your convenience.

Do you have a return policy?

We offer a 10-day return policy on our cartridge-filling machines and other products.

Please contact us via phone or email with your name, order number, address, and machine model you ordered to start the return process.

Privacy Policy

Our company does not sell your information to any third parties.

Our website is 100% secure and we only ask for your contact information,

such as phone number and email,

so that we may contact you about your order.

Terms of Service

All images and information on the website are either property of Credence Filling Systems or licensed.

When visiting our site, you are agreeing to appropriately use all content and follow all copyright laws.

If any image or content is found to be used without permission, legal action may be brought against the offender.